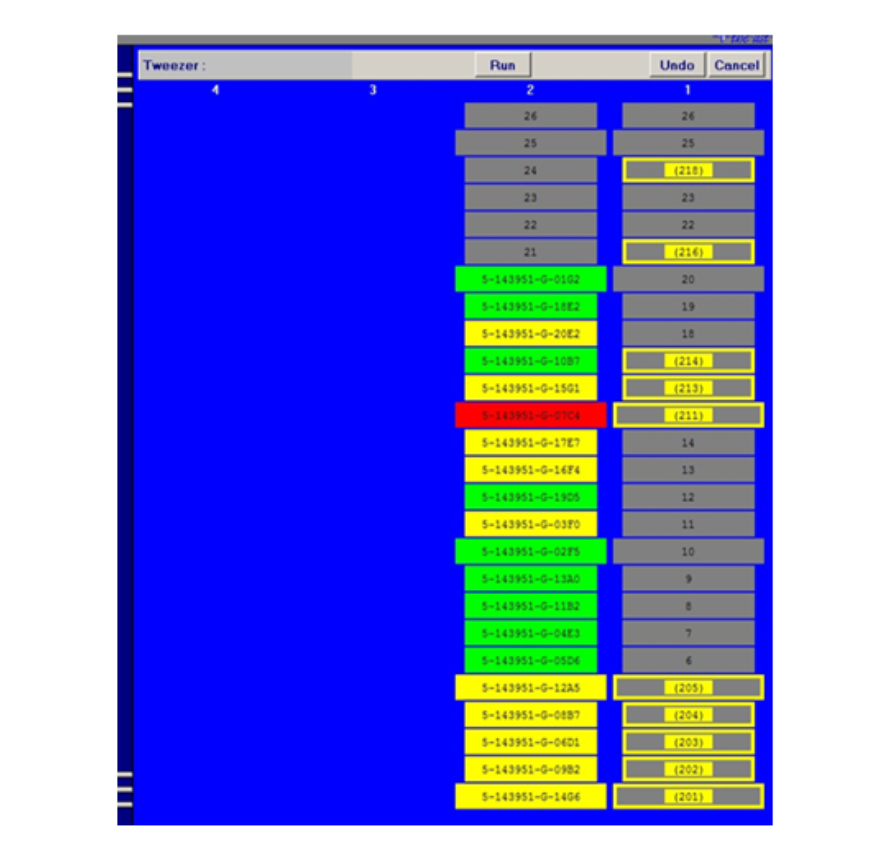

EAGLEview offers a full range of sorting options. During an inspection, EAGLEview performs OCR to read wafer scribes. After an inspection, engineers can specify sorting routines for specific levels and/or devices that occur without operator intervention. Wafer sorting flexibility includes the ability to perform typical sorting routines and advanced sorting such as placing specific wafers into specific slots. If needed, the macro inspection mode can be stopped to allow the tool to sort wafers using a “virtual tweezer” mode (i.e. click on source and destination slots to automatically move both individual and/or groups of wafers) on the tool’s user interface in one operation.

Customized Automatic Sorting

EAGLEview offers a full range of sorting options. During an inspection, EAGLEview performs OCR to read wafer scribes. After an inspection, engineers can specify sorting routines for specific levels and/or devices that occur without operator intervention. Wafer sorting flexibility includes the ability to perform typical sorting routines and advanced sorting such as placing specific wafers into specific slots. If needed, the macro inspection mode can be stopped to allow the tool to sort wafers using a “virtual tweezer” mode (i.e. click on source and destination slots to automatically move both individual and/or groups of wafers) on the tool’s user interface in one operation.

Download Microtronic Macro Defect Brochure

Microtronic Overview Video

Navigation

Social connect